Brochure

Pressure Vessels and Equipment

This list includes Pressure Vessels, Pig Handling systems - Pig Launcher, Pig Receiver, Jib Crane, Trolley, Filters, Reactors, Storage tanks, Separators, Columns, Gas cylinders, Auto claves.

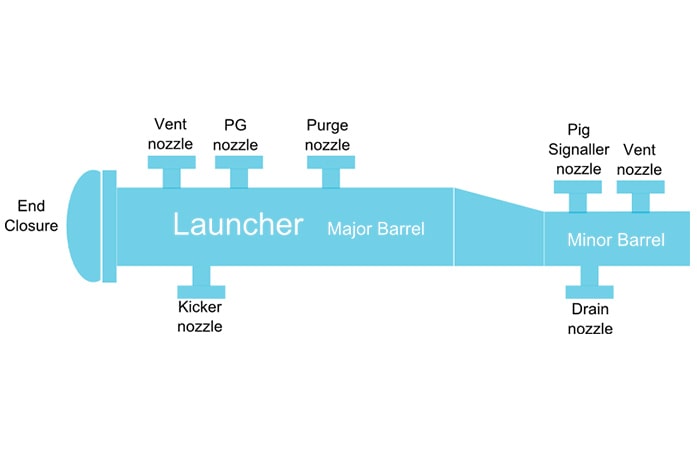

Once We work with pipeline, over a period of time their cleaning, maintenance and delineation is required. Considering that these pipelines are carriers of high pressure substance, quality pig handling systems for Cross Country pipelines are carriers of high pressure substance, quality Pig handling Systems are must to complete ARD Systems INC's Portfolio. Pig handling systems for Cross Country pipelines and process plants have been supplied successfully by us. These systems are supplied with pig indicators and necessary valves and safety equipment to ensure safe and smooth launch and receipt of pigs. These systems can be readily installed and easily mounted at site with all factory tested accessories. Our Pig Handling systems are fitted with custom made pig handling cranes and trolley systems for our clients.

Pressure Vessels

Behind vast experience in this industry, we have been capable enough to provide customers with high quality and long lasting Pressure Vessels. Pressure Vessels offered by us are manufactured in compliance set by industry standards and norms.

Our vessels are manufacture with premium quality of raw material and latest tools and machinery. We have tested our vessels on various parameters to ensure its flawlessness and durability.

We manufacture vessels for water treatment plants, gas storage and refrigeration. Our vessels are export at shipping industries, automotive industries and power industries. We are open for customized vessels for any sort of requirement.

Knock Out Drum/ Scrubber /Separator are the best solution to the problem of separation of liquid particles or vapor mist form gas or any other media. Vane bundle which forms the heart of the vane separator employs the principle of centrifugal force, impingement and gravity. The liquid laden gas entering the vane separator is a mixture of low density gas and high density liquid. As this mixture passes through the vane bundle, it is forced to change direction several times. The high density liquid is unable to change direction without impinging on liquid walls, while the low density gas can easily negotiate the tortuous path. A tech change in direction a centrifugal force is imparted on the gas liquid mixture which throws the liquid particles against the wetted vane walls.

Dry Gas Filter is a multi stage filer that provide maximum solid & liquid removal. The primary stage of separation is designed for removal of large solid and liquid particulate though gravitational & centrifugal force. It is however to be noted that if high solid or liquid slugs are present then additional separation internals viz multitude cyclone must be installed to provide bulk removal and extend life of the coalescing element. The gas then enters the final stage of separation consisting of special multi layered fiber glass coalescing elements. These filters elements are chosen according to the type of filtration efficiency and allowable pressure drop.