Brochure

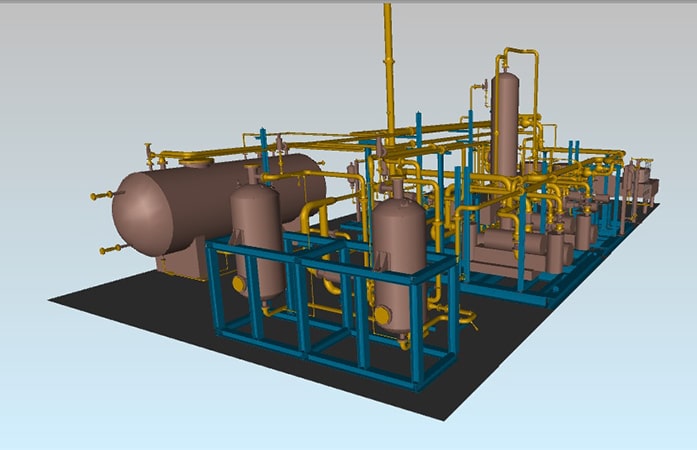

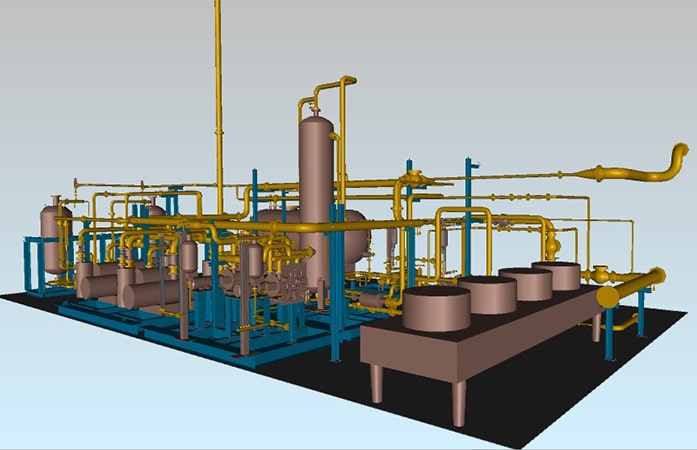

Vapour Recovery Skids

The basic system of gasoline Vapor Recovery unit works on the principle of pressure swing adsorption(PSA). the system consists of two carbon vessel to ensure continuous operation. One adsorber vessel is always on stream in adsorption (separation) mode, where as other adsorber is in desorption (recovery) mode. Vapor enters one of the vessels and passes through bed activated carbon.

Hydrocarbons are adsorbed in activated carbon allowing hydrocarbon free air to exit to atmosphere, simultaneously second adsorber is being re generated. For re-generation, vessel is evacuated by suitable vacuum pumps to the desired vacuum level. This is followed by small air purging through the vessels during last phase of regeneration. Vacuum followed by air purge pulls out all the hydrocarbons from the activated carbon, passes through the absorber column and phase separator.

Hydrocarbon vapor passes through the adsorber packing, where it is condensed by circulating gasoline. This circulating gasoline will also cool vacuum pump seal fluid. The condensed gasoline vapor is mixed with the circulating gasoline which is returned to the system. all unadsorbed vapor/air which exits through the top of the absorber is returned to the absorber which is on adsorption mode(separation mode). System is equipped with programmable logic controller with PC based user friendly human machine interface. This facility will ensure remote operational adjustment & fault diagnostic service with eases.