Brochure

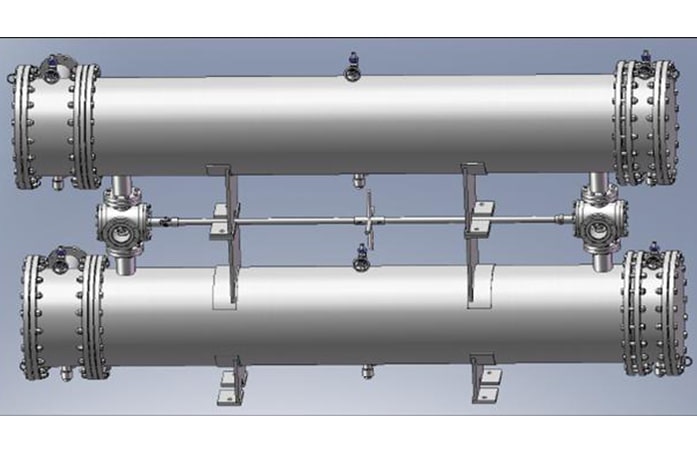

Duplex Lube Oil Coolers

Lube oils and the Functions it is used for in turbine- generation are necessary for optimal production for the moment, and optimum Equipment reliability for the future. Both production and reliability are essential elements of increased profits. For lube oil to do its job it must be kept clean and at the proper temperature. Lube oil coolers are an essential element in this process.

The primary purpose of lube oil coolers is to cool turbine oil. This is accomplished as the heated oil travels a serpentine path through the shell side of the bundle, while Cooling water flows through the tube side. Heat is transferred from the oil to the water, keeping the oil temperature within its ideal operating range.

As the oil travels this serpentine path through the cooler, the heat transfer causes foreign materials in the oil to drop out and adhere to the outside of the tubes. This is a two edged sword. First, the build up on the shell side of the tubes becomes an insulator reducing the ability of heat to be transferred. Then, as the buildup of contaminates continues, sections of bundle will become plugged, restricting the flow and further reducing Heat Exchange. Eventually, some of this material will move through the bundle and cause premature wear on the bearings and other.